HVAC & Piping System Installation

K&T JV prioritizes hands-on practical training for customer technicians on the complete range of solutions for both piping and HVAC. This training is offered either at our offices, the customer's office, or directly at the job site.

Refrigeration Cycle

Understanding of refrigeration principles and practices, including the handling and charging of refrigerants.For more information see below contents

Soft Skills

Communication. Problem-Solving. Time Management. Customer Service. Attention to Detail. Physical Fitness.

|

Types of HVAC Systems |

Central Heating and Cooling Systems |

Ductless Mini-Split Systems |

Ventilation Systems |

Geothermal Heat Pumps |

Radiant Heating and Cooling |

|---|---|---|---|---|---|

Defination |

Central HVAC systems are the most common type found in many homes and commercial buildings. They provide both heating and cooling from a central location and distribute conditioned air throughout the building through a network of ducts. | Ductless mini-split systems are more flexible alternatives to central HVAC systems. They consist of one or more indoor air-handling units connected to an outdoor compressor unit. | Ventilation systems focus on supplying fresh air and exhausting stale air to maintain indoor air quality. They are often combined with heating and cooling systems. | Geothermal heat pumps use the consistent temperature of the ground or water as a heat source in the winter and a heat sink in the summer. | Radiant systems use heated or cooled surfaces (such as underfloor heating or wall panels) to directly transfer heat to or extract heat from the indoor environment. |

Components |

Furnace: Used for heating by burning fuel (natural gas, propane, oil) or using electric resistance coils. Air Conditioner or Heat Pump: Provides cooling during the warm months and heating during the cold months. Ductwork: A system of ducts that carry conditioned air to different rooms. Thermostat: Controls the temperature and operation of the system. |

Indoor Units: Mounted on walls or ceilings in individual rooms or zones. Outdoor Unit: Houses the compressor and condenser. Refrigerant Lines: Connect the indoor and outdoor units Remote Control or Thermostat: Used to control each indoor unit. |

Air Intake and Exhaust Fans: Bring in and expel outdoor and indoor air. Filters: Remove particulate matter and pollutants from incoming air. Heat Recovery Ventilator (HRV) or Energy Recovery Ventilator (ERV): Recovers heat or energy from outgoing air to pre-condition incoming air. |

Ground Loop: Buried pipes or loops filled with a heat-transferring fluid. Heat Pump Unit: Indoor unit that exchanges heat with the ground loop. |

Pipes or electric elements embedded in floors, walls, or ceilings. |

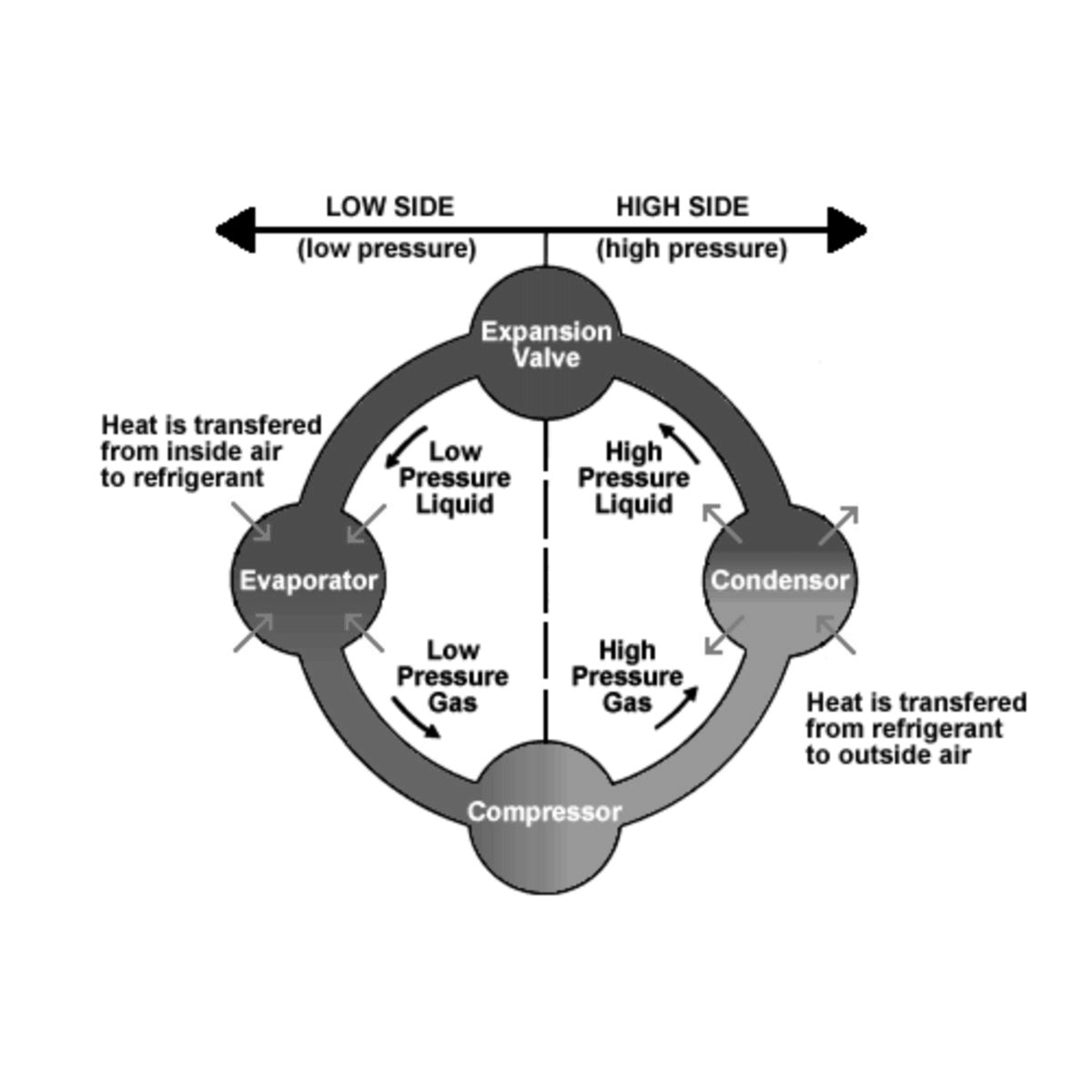

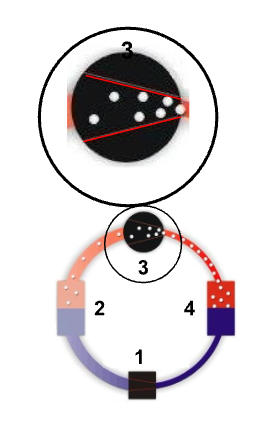

Refrigeration Cycle

The Expansion Valve

The high-pressure liquid refrigerant passes through an expansion valve or an orifice.

As the refrigerant passes through this valve, it undergoes a sudden drop in pressure, causing it to expand and cool rapidly.

The refrigerant exits the expansion valve as a low-pressure, low-temperature mixture of liquid and vapor, ready to enter the evaporator coil and start the cycle a new.

Refrigeration

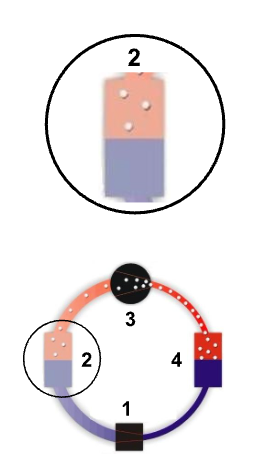

EVAPORATOR In the evaporator, the refrigerant changes its condition from liquid to gas (boils) and absorbs heat from its environment in the process.

The room -air, supported by a fan, is being forced over the evaporator. It consists of a Lamelle Exchange, which exhausts the heat.

Embedded in the lamella exchanger run copper-tubes, through which the refrigerant circulates.

The compressor compresses the refrigerant-gas to a higher pressure- and temperature level and pumps the created hot-gas to the "liquidator“ (heat-exchanger).

The created vacuum in this process extractes the refrigerant-gas from the evaporator.

This process ensures a continuos supply of the refrigerant-gas and keeps the "cycling-process“ running.

Refrigeration - The Compressor

The compressor compresses the refrigerant-gas to a higher pressure- and temperature level and pumps the created hot-gas to the "liquidator“ (heat-exchanger).

The created vacuum in this process extractes the refrigerant-gas from the evaporator.

This process ensures a continuos supply of the refrigerant-gas and keeps the "cycling-process“ running.

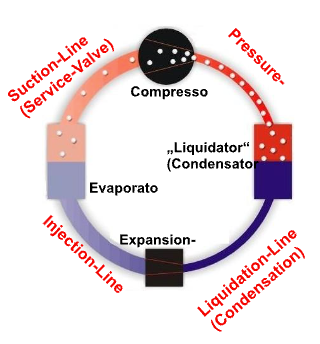

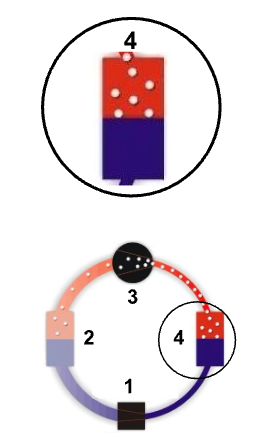

The Refrigeration Cycle

The hot refrigerant-gas releases its heat in the condenser via a lamella-heat-exchanger to the atmosphere (outside).

The released heat-energy consists of the absorbed heat-energy (in the evaporator) and the compression-energy from the compression process.

The "liquidation-process“ (condensation) is comparable to the evaporation-process, however the change of the condition of the refrigerant is reverse, i.e. from gas-form to liquid-form.

- Pressure-Line – carries compressed Refrigerant-gas from the compressor to the condensor (incl. liquid oil, temp.: 80-160°C)

- Condensation-Line – liquid refrigerant flows to the expansion valve.(Oil is absorbed)

- Injection-Line – transports a gas-/liquid mixture to the evaporator

- Suction-Line – connects the evaporator and the compressor (refrigerant gas)