BU# 10 Bending Tools

Achieve Perfect Bends Every Time with Our Advanced Pipe Bending Machine

Introducing the Ultimate Pipe Bending Solution for Professionals

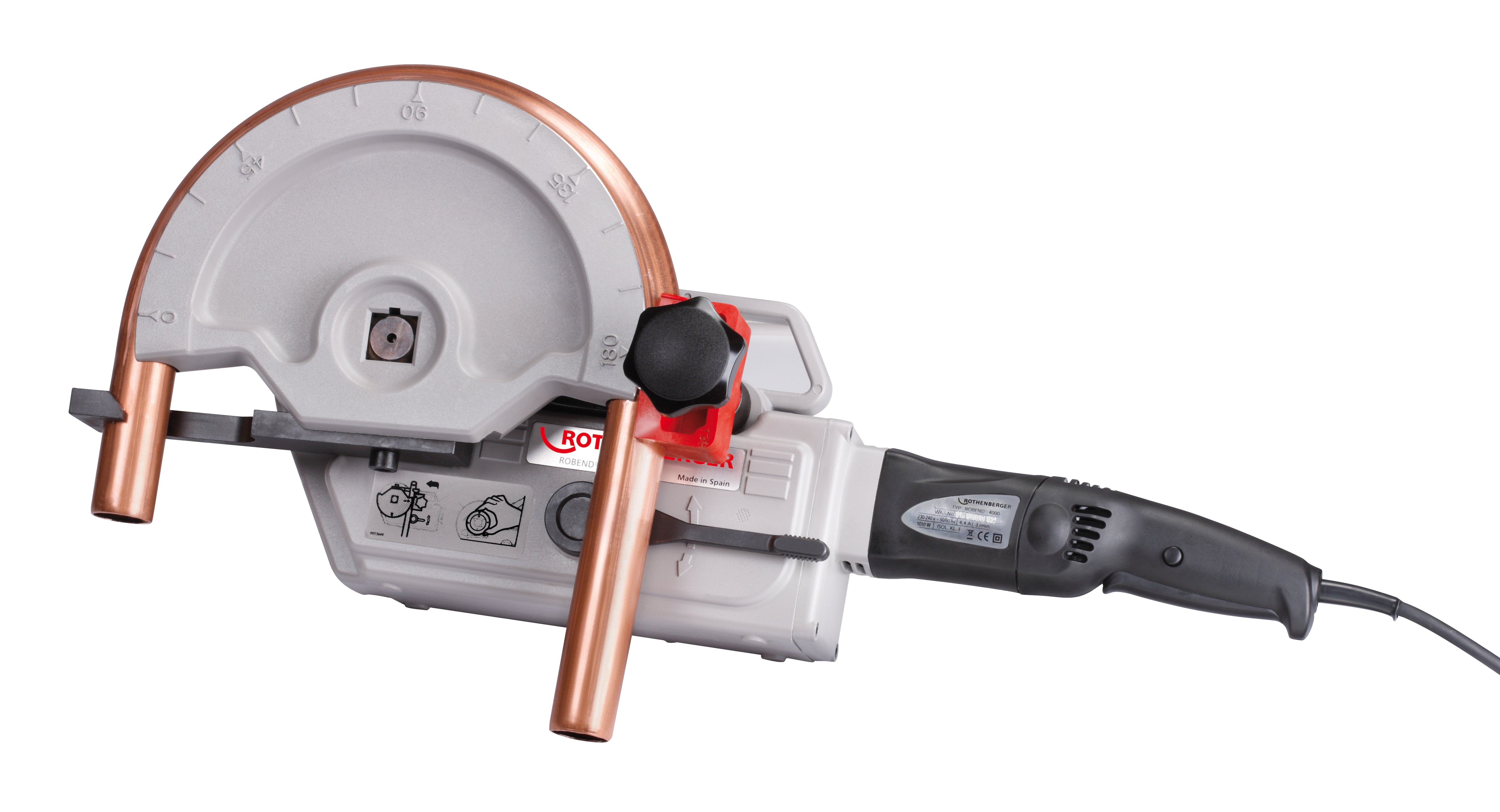

Elevate your pipe installation projects with our state-of-the-art pipe bending machine, designed to seamlessly bend pipes from 0° to 180° across diameters ranging from 12 to 35 mm (1/2 to 1.3/8 inches). This machine is a game-changer for professionals in plumbing, heating, refrigeration, and more, ensuring less joint use, fewer leaks, and a significant reduction in the risk of injuries.

Unmatched Versatility and Precision in Pipe Bending

- Rapid Return on Investment: Save on costs associated with joints, soldering, and energy, enhancing your project's efficiency and profitability.

- Broad Application Range: Whether you need U-bends, counter-bends, swan-neck bends, or connecting bends, this machine delivers with precision at any level.

- Durability and Stability: Benefit from high-quality forged aluminum bending formers that guarantee stability and longevity.

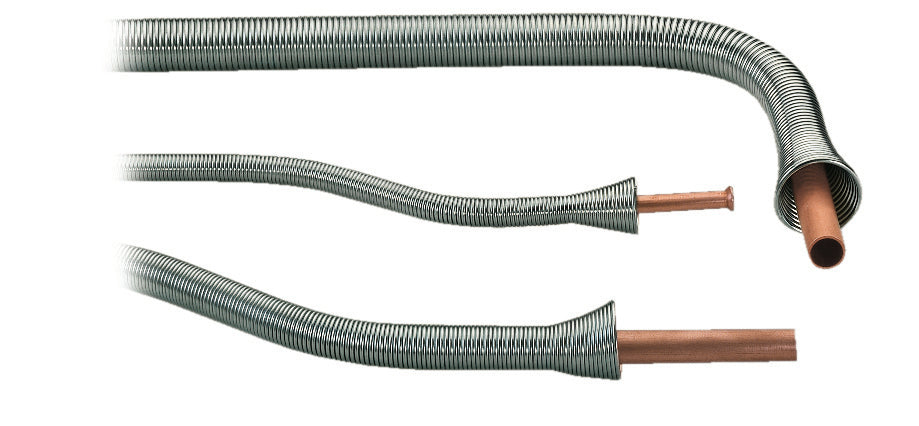

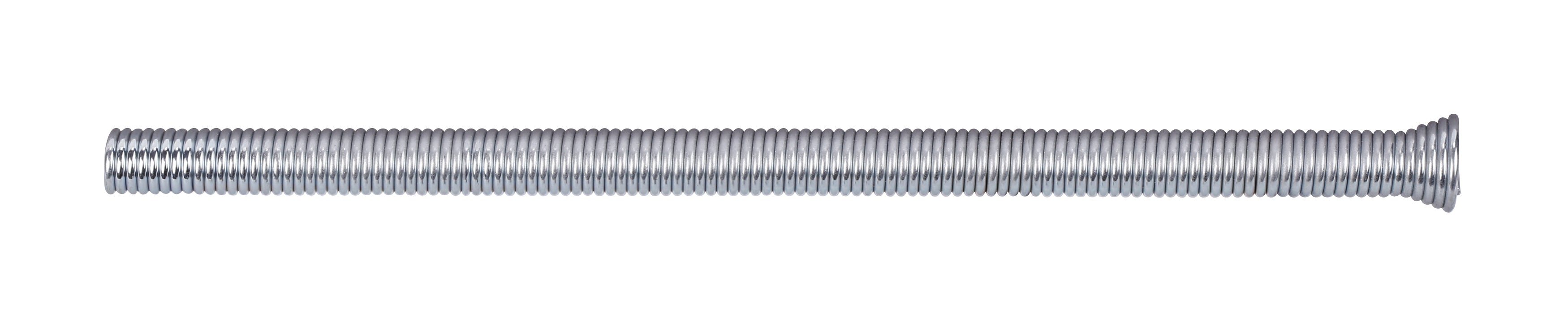

- Flawless Bends Without Effort: Achieve bends free of deformation or ripples, thanks to reduced friction and our advanced bending technology.

Key Features That Set Our Machine Apart:

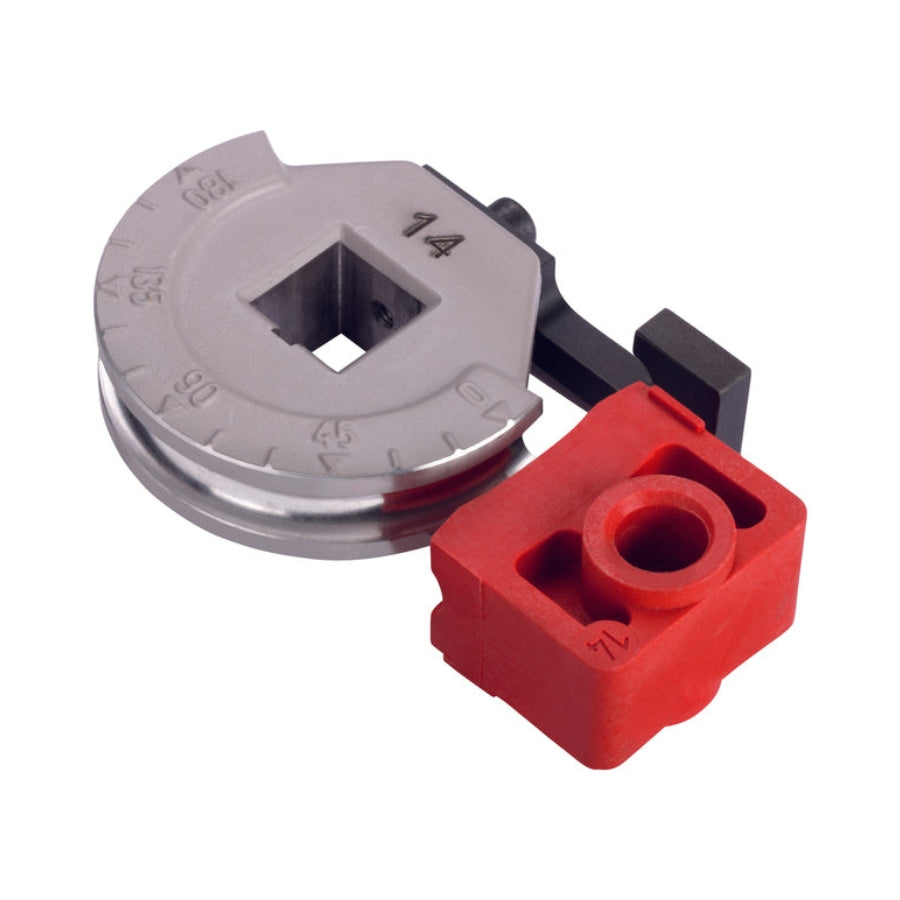

- Seven Fold Drive & Forged Aluminum Segments: Experience powerful transmission even with larger diameters, complemented by stable bending segments complete with angle indicators.

- Brushless Motor & Curved LUB Bending Shoe: Enjoy faster operation and seamless bending, minimizing friction and preventing deformations.

- Kinematic Chain for Smooth Operation: A reduction from 32,000 r.p.m through a kinematic chain ensures uniform motor operation, delivering consistent results.

- Innovative Safety and Convenience Features: With features like mechanical speed change, instant stop at desired angles, and a safety switch with locking protection, our machine is designed for both efficiency and safety.

Wide Range of Applications:

Suitable for various pipe materials including hard, semi-hard, and soft copper (DIN EN 1057, 12735-1, 13348), coated copper and precision steel (Ø 12–28 mm), soft precision steel (DIN 2391 / 2393 / 2394), threaded steel (DIN 2440 / 2441), and seamless stainless steel (GW 541), our machine offers unparalleled flexibility.

Featured product

$0.00 CAD

Filters

10 products