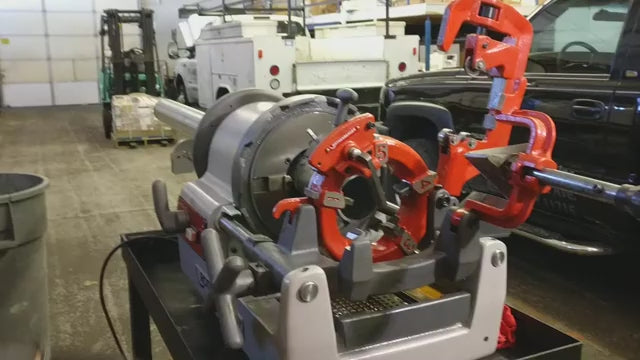

THREADING AND GROOVING - ELECTRIC 4 KT RANGE DIA 1/2" TO 4"

Tool Description

High-Performance Threading Tool for Professionals | ELECTRIC 4 KT with Universal Applications

Introducing the ELECTRIC 4 KT, a threading tool engineered for reliability and versatility in professional settings. Whether for portable or stationary use in workshops, on-site, or for pipeline construction, this tool is designed to meet the demands of trade, industry, sanitary, and heating installations. Its universal application allows for operation with or without a stand, ensuring flexibility in any work environment.

Enjoy a host of application benefits including universal die head seating for both standard and automatic options, ensuring precise and low-wear operation. The smooth action impact hammer chuck provides maximum clamping force, preventing pipe slippage and ensuring secure operation. With its modular system concept, this tool is adaptable and can be used alongside roll grooving tools for added functionality.

Key features like the self-centering rear chuck, internal 3-blade deburrer, and dual-sided tool guide sled ensure precise, burr-free threading and easy pipe alignment. The robust oil pump offers optimal lubrication, while the large shavings collection trough keeps your workspace clean. Designed for fast, efficient threading with automatic die heads for quick thread size adjustments, the ELECTRIC 4 KT sets the standard for professional threading tools.

Application Benefits

| Working area | Dia 1/2" - 4" |

| Power consumption | 1750W |

| Idle speed | 0-33RPM |

| Thread type |

BSPP, BSPTR, BSW, METRIC, NPT |

Key Product Features & Benefits

| Feature Description | Double insulated Motor as per VDE |

Machine slightly angles | Geared oil pump with filter |

Trolley with two wheels included |

|

Benefits |

Safe Operation |

Reduced oil consumption, oil coating in pipe interior is avoided |

Constant oil flow |

High mobility |

Product Videos

FEATURES

APPLICATIONS

TECHNICAL DATA

OPERATING INSTRUCTIONS

SUPPORT

Cross-Product Recommendations

Dit product heeft een beoordeling van 5.0 van 5.0 sterren.

Het heeft 1 recensie gekregen.

Disclaimer for Product Reviews

K&T JV does not assume responsibility for, nor does it endorse, the content of any posted product review or statement. The statements expressed belong solely to the poster and do not reflect the views of K&T JV. K&T JV does not make any assurances regarding the appropriateness, accuracy, completeness, correctness, currentness, suitability, or validity of the product reviews or statements, even those posted by K&T JV Ltd employees. The company is not accountable for any losses, injuries, or damages that may arise from such product reviews or statements. Users engage with any linked website provided in a product review or post at their own risk. For further details, please refer to the Terms and Conditions.