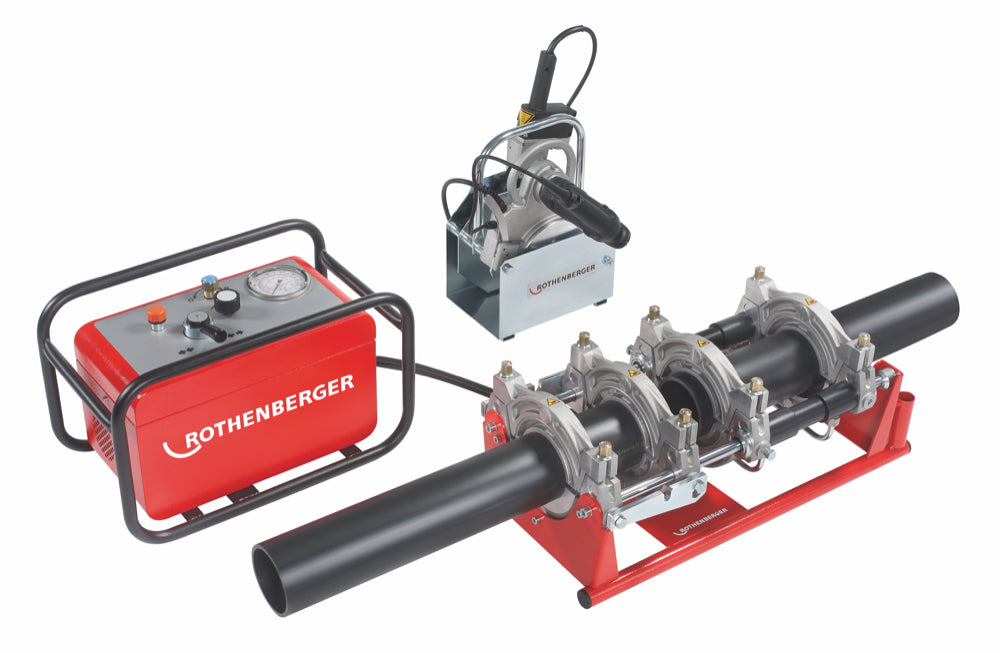

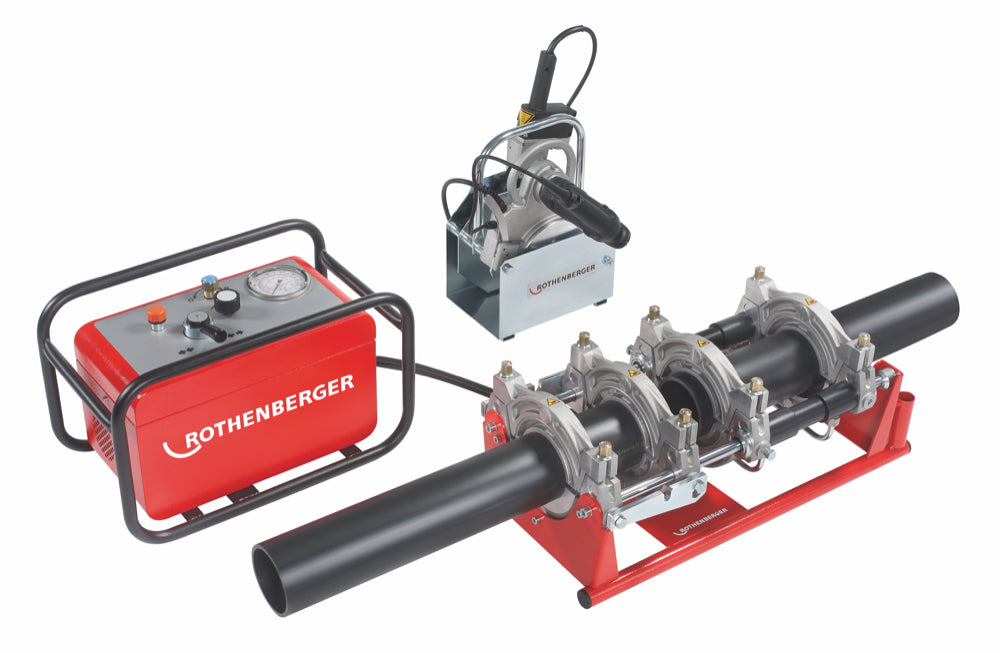

PLASTIC PIPE BUTT WELDING 250 - RANGE 90MM TO 250MM

Tool Description

Application Benefits

-

Versatile Application: The system is engineered to perform in various settings, from on-site construction areas and pipe trenches to controlled environments within workshops. Its adaptability ensures that quality welding can be achieved regardless of the location.

-

Durable and Lightweight Construction: The use of high-quality materials that are both durable and lightweight enhances the system's longevity while making it easy to transport and set up, an essential feature for field applications.

-

Robust, Low-Maintenance Design: Designed to be compact and robust, the welding system withstands harsh operational conditions and requires minimal maintenance. This reliability reduces downtime and operational costs, providing a more efficient workflow.

-

Precise Hydraulic System: The system's hydraulic components, including an infinitely variable pressure adjustment and a pressure accumulator, allow for precise control over the welding process. This precision ensures consistent, high-quality welds.

-

Easy-to-Read Pressure Gauge: The inclusion of an easy-to-read pressure gauge aids operators in monitoring and adjusting the welding pressure accurately, contributing to the overall quality and integrity of the welds.

-

Electronic Temperature Control: The electronic control of the heating element temperature ensures that the heat is consistently applied at the optimal level for welding PE, PP, and PVDF pipes and fittings, resulting in strong, reliable joints.

-

Efficiency and Productivity: With features designed to enhance the precision and reliability of the welding process, the system contributes to greater operational efficiency and productivity, saving time and resources on projects.

-

Enhanced Safety Features: The system is equipped with safety features that protect the operator and the equipment, further ensuring reliable operation and longevity of the system.

| Pipe Welding Range Dia (mm) | 63mm - 200mm |

| Pipe Capacity | SDR series see welding table + Observe Pressure max. hydraulic unit |

| Cylinder stroke, max (mm) | 150 |

| Total Cylinder Surface (cm square) |

6.26 |

|

Trimmer Power |

230V,60Hz,3.5Amp |

| Rated Power Input | 750W |

| Rated Power Output | 470W |

| Rotary Speed per min | 660 |

| Idle Running Speed per min | 85 |

| Heating Plate Power | 230V,60Hz,1500W |

| Heating Plate Diameter (mm) | 300 |

| Heating Plate weight(kg) | 5.5Kg |

| Carrying Frame weight (kg) | 8.2kg |

| Hydraulic Power supply | 230V-60Hz-2.5Amp |

| Rated Power Input | 670W |

| Rated Power Output | 370W |

| Pump Capacity (l) | 2.45 |

| Oil Tank Capacity (l) | 0.7 |

| Pressure Max. (bar) | 100 |

| Hydraulic Oil | HLP 46 |

| Dimensions (lxbxh,mm) | 540x340x340 |

| Overall Connected Load (Kw) | 2.9 |

| Transport Case Dimensions (lxbxh,mm) | 1200x800x900 |

Key Product Features & Benefits

| Feature Description | Robust,Torsionally Rigid Frame |

Flexible | Simple Operation in Hydraulic unit | Triple Coating of Heating Element |

| Benefits | Allows reliable welding in virtually any environment |

The 3rd basic clamping element can be moved flexibly | Allow precise start up of the pressure | Longer lifetime,and even distribution of heat for better welding results |

Product Videos

FEATURES

APPLICATIONS

TECHNICAL DATA

OPERATING INSTRUCTIONS

SUPPORT

Cross-Product Recommendations

Este producto aún no tiene reseñas.

Disclaimer for Product Reviews

K&T JV does not assume responsibility for, nor does it endorse, the content of any posted product review or statement. The statements expressed belong solely to the poster and do not reflect the views of K&T JV. K&T JV does not make any assurances regarding the appropriateness, accuracy, completeness, correctness, currentness, suitability, or validity of the product reviews or statements, even those posted by K&T JV Ltd employees. The company is not accountable for any losses, injuries, or damages that may arise from such product reviews or statements. Users engage with any linked website provided in a product review or post at their own risk. For further details, please refer to the Terms and Conditions.