Join Plastic / SS / Copper or Galvanised pipes and Test for Leakage.

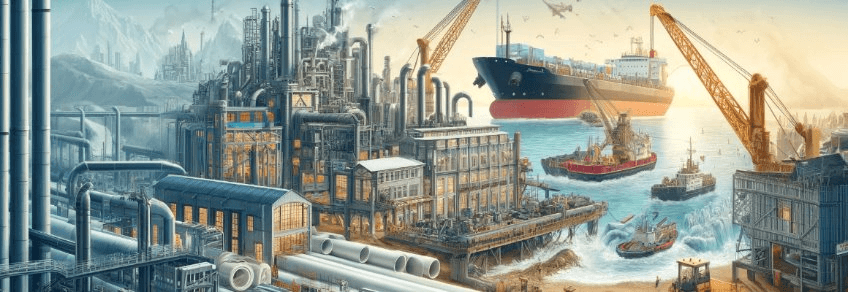

Elevate your Industrial Manufacturing, Plastic Pipe Fabrication, Marine & Shipbuilding, and Mining operations with our extensive range of machines, including fusion, press, butt welding, grooving, threading, and electric testing pumps, all embodying swift and dependable German technology for unmatched performance.

Enhance your understanding by watching our video under the View More button where we are showcasing how our tools swiftly and efficiently solve applications with minimal or NO error

Joining Gas / Water HDPE Pipes

In shipbuilding, it's used to join plastic pipes that are part of the water systems on board, ensuring they withstand the harsh marine environment. In Mining it provides robust pipe connections vital for the heavy-duty and safety-critical pneumatic and hydraulic lines used in mining operations.

Joining Metal / SS pipes

Utilized for the assembly of piping systems on ships, where the integrity of every connection is vital for the vessel's safety and operation in the demanding marine environment.In mining, the press machine is crucial for assembling robust piping systems that can withstand the harsh conditions and pressures underground.

Large Diameter HDPE Joining - Butt Welding

In Mining it supports the construction of robust piping infrastructures needed for slurry transport and various other demanding applications.In Plastic Pipe Manufacturers this machine is central to their operations, allowing for the production of long, continuous pipe systems with uniform strength throughout.

Fire Fighting -Grooving Technology

Marine & Shipbuilding: It's used for creating precise grooves in pipe ends, allowing for a secure mechanical joining method that is vital for the ship's water-tight piping systems which must endure the constant motion and saline environment at sea..

Joining Galvanised Pipes - Threading

Marine & Shipbuilding: Ensures water-tight connections for piping on ships, critical for systems ranging from bilge to fuel, in a sector where joint integrity is crucial for safety and seaworthiness.It provides accurate threading for secure pipe connections essential in automated and manual production systems.

Pressure Testing - Self Priming Pump

This pump is key for quality control, checking the welds and joints in pipe systems to ensure they can withstand the operational pressures without failing.In Manufacturing:To test the integrity and leak-resistance of various components and systems under pressure.